When you pick up a generic pill at the pharmacy, you expect it to work just like the brand-name version. But what if it doesn’t? Behind the scenes, manufacturing plants around the world are struggling with systemic quality problems that put patient safety at risk. These aren’t rare mistakes-they’re widespread failures tied to how generic drugs are made, inspected, and regulated.

What Goes Wrong in Generic Drug Manufacturing?

Generic drugs are supposed to be exact copies of brand-name medicines. But copying a pill isn’t as simple as it sounds. It’s not just about matching the active ingredient. The chemical structure, how the drug dissolves in your body, how it’s packaged, even the tiny impurities that form during production-all of it matters. One of the biggest red flags is impurities. In 2018, the FDA found N-nitrosodimethylamine (NDMA), a known carcinogen, in blood pressure medications like valsartan. The contamination came from a manufacturing process change at a plant in China that wasn’t properly tested. That single issue led to 28 recalls across 22 countries. NDMA didn’t show up because of a one-time error. It showed up because the facility didn’t have proper controls to detect or prevent it. Other common problems include:- Incorrect dissolution rates-drugs that don’t break down properly in your stomach

- Poor packaging that lets moisture in, ruining the medicine

- Inadequate stability testing, meaning the drug might lose potency before its expiration date

- Substandard raw materials from unverified suppliers

Why Are Foreign Plants More Problematic?

About 80% of the active ingredients in your pills come from just two countries: China and India. The rest of the world relies on them. But inspections tell a troubling story. In 2022, FDA inspections found that facilities in China had 28.6% more quality violations per inspection than U.S. plants. Indian facilities had 19.3% more. Why? One big reason: inspections aren’t random. In the U.S., the FDA can show up unannounced. In foreign countries, they have to give notice-sometimes weeks in advance. That gives plants time to clean up, hide documents, or even temporarily hire extra staff to pass the audit. A 2023 study from Ohio State University found that generic drugs made in India were linked to 23.7% more severe side effects than those made in the U.S. The FDA only inspects about 13% of foreign facilities each year. There are nearly 3,000 of them. The agency doesn’t have the staff, the budget, or the access to check them all. And even when they do, they rarely test the actual pills. Only 0.02% of imported drug shipments undergo lab analysis. That means most of the time, regulators are trusting paperwork-not the product.How Quality Control Falls Apart

Good manufacturing practices (cGMP) aren’t optional. They’re the law. But many plants cut corners to save money. One of the most common failures? Poor data integrity. In 2022, 78.3% of data-related FDA violations involved:- Missing audit trails

- Shared passwords

- Deleted electronic records

The Cost of Cutting Corners

Generic drugs are cheaper because manufacturers compete on price. But that race to the bottom is hurting quality. Between 2018 and 2022, the average price of generic drugs dropped by 18.3% annually. In response, companies slashed quality control budgets by 22.7%. Fewer tests. Less equipment maintenance. Less staff. Less oversight. The result? Drug shortages. In 2022, 58.7% of all drug shortages in the U.S. were caused by quality issues at foreign manufacturing plants. Medications like heparin (a blood thinner), nitroglycerin (for heart attacks), and antibiotics disappeared from shelves because the plants couldn’t meet standards. Patients noticed. A 2022 survey of hospital pharmacists found that 67.3% had seen at least one generic drug fail in practice-meaning a patient didn’t respond to it the way they should have. Over 42% blamed products made in India. On patient review sites, generic valsartan from one Chinese manufacturer got a 3.2-star rating. The U.S.-made version? 4.1 stars. Over 28% of the negative reviews said the drug just didn’t work.Who’s Responsible?

The FDA is supposed to protect you. But its system is outdated. It relies on self-reported data. It can’t test every batch. It can’t inspect every plant. And it doesn’t have the power to shut down foreign facilities without cooperation from their governments. Experts like Dr. Aaron Kesselheim from Harvard have shown that 15.2% of generic drugs on the FDA’s Watch List aren’t therapeutically equivalent to their brand-name counterparts. One example: tacrolimus capsules, used after organ transplants. The generic versions showed 28.4% more variation in blood levels. That’s dangerous-too little and the body rejects the organ; too much and it causes kidney damage. The Hatch-Waxman Act of 1984 made generics faster and cheaper to approve. But it didn’t account for complex drugs. Today, proving bioequivalence for a simple pill takes a few tests. For a modified-release capsule or a narrow-therapeutic-index drug, it takes 37% more testing. Yet many manufacturers still submit incomplete data.

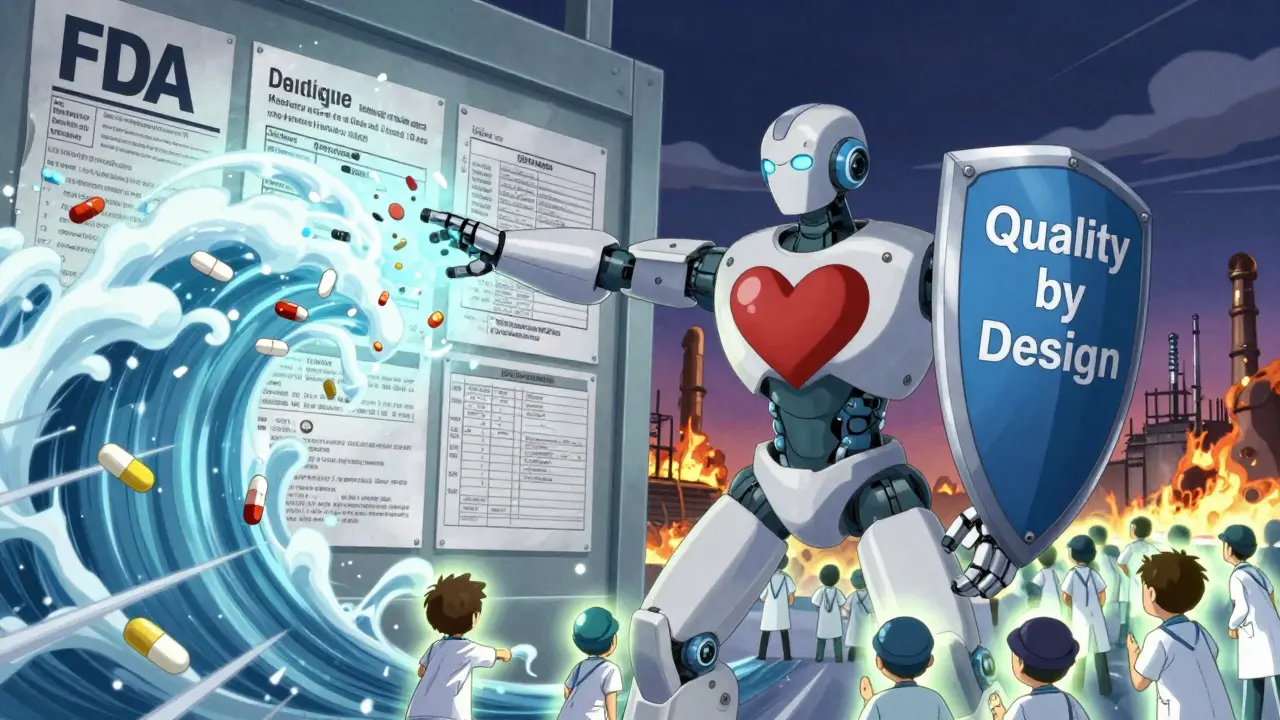

What’s Being Done?

There are signs of change. The FDA’s 2023-2027 plan says it will prioritize inspections of high-risk facilities. It’s aiming to increase foreign inspections from 1,200 to 1,800 per year by 2027. The European Medicines Agency already does unannounced inspections-and has seen a 41.2% jump in critical findings. Some manufacturers are stepping up. The Quality by Design (QbD) approach builds safety into the process from day one. It defines exactly what makes a drug work, how to control it, and what to monitor. But only 23.8% of generic makers use it. It costs $2.7 million and takes 18-24 months to implement. Most can’t afford it-or won’t. The government is trying to help. The FDA’s user fees for generic applications rose 62.9% from 2018 to 2023. That money is supposed to fund more inspectors and better tech. But progress is slow.What You Can Do

You can’t inspect a factory. But you can be aware. - If a generic drug stops working for you, talk to your pharmacist. Ask if it’s from a new manufacturer. - Report side effects to the FDA’s MedWatch system. Every report matters. - If you take a life-saving drug like warfarin, thyroid medicine, or epilepsy treatment, ask if there’s a brand-name alternative you can afford. - Check the FDA’s Drug Shortages list. If your medication is on it, your pharmacy might be switching brands-and that’s not always safe. Generic drugs saved the U.S. healthcare system billions. But they’re only as good as the factories that make them. And right now, too many of those factories are cutting too many corners.What’s Next?

The next few years will decide whether the system can fix itself. If manufacturers don’t invest in real quality, more recalls, more shortages, and more harm to patients are coming. If regulators finally get the tools and authority to enforce real oversight, patients might start getting the safe, effective medicines they paid for. For now, the system is broken. And the cost isn’t just financial. It’s measured in lives.Are generic drugs less effective than brand-name drugs?

Most generics work just as well as brand-name drugs. But not all. Studies show that 15.2% of generics on the FDA Watch List have therapeutic differences-meaning they don’t deliver the same effect in the body. This is most common with complex drugs like blood thinners, epilepsy meds, and transplant drugs. If your generic suddenly stops working, it could be a quality issue, not your body changing.

Why do some generic drugs come from China and India?

Because it’s cheaper. Manufacturing drugs in China and India costs far less than in the U.S. or Europe. About 80% of active ingredients and 40% of finished pills come from these countries. But lower cost often means lower oversight. The FDA inspects only a small fraction of these facilities each year, and they usually get advance notice-making it easier for plants to hide problems.

How can I tell if my generic drug has quality issues?

Look for changes: Did your pill look different? Did it taste odd? Did you start having side effects you didn’t have before? Did your condition suddenly get worse? If so, talk to your pharmacist. Ask which company made it. You can also check the FDA’s Drug Shortages list or search for recalls by the manufacturer’s name. If you’re on a critical medication, don’t assume all generics are equal.

What are nitrosamines, and why are they dangerous?

Nitrosamines are chemical impurities that can form during drug manufacturing. They’re known carcinogens-meaning they can cause cancer with long-term exposure. In 2018, they were found in blood pressure meds like valsartan. The contamination came from a change in the chemical process that wasn’t properly tested. The FDA recalled millions of pills. Since then, stricter testing rules have been added, but not all manufacturers follow them.

Why doesn’t the FDA test every batch of generic drugs?

It’s not practical or funded. The FDA inspects facilities, but it doesn’t have the budget or staff to test every single batch of every drug coming into the U.S. Only 0.02% of imported drug shipments are lab-tested. Instead, the agency relies on manufacturers’ own test results and inspection reports. This system works only if companies are honest-and too often, they’re not.

Are there safer generic drug brands?

Some manufacturers have better reputations. Companies based in the U.S., Canada, or the EU tend to have fewer violations. Look for generics made by large, established firms like Teva, Mylan, or Sandoz-though even they’ve had recalls. Avoid unknown brands, especially those from plants with a history of FDA warning letters. If your doctor or pharmacist recommends a specific generic, ask why.

Post A Comment